Thermal Stability and High-Temperature Performance of Magnesium Oxide

Exceptional Melting Point Enabling Use in Extreme-Temperature Environments

Magnesium oxide, commonly known as MgO, melts at around 2800 degrees Celsius which puts it right up there with the top refractory oxides when it comes to heat stability. Materials made from MgO can hold their shape even in super hot conditions like inside industrial furnaces, nuclear reactor components, and parts of spacecraft that need protection from extreme temperatures. To put things into perspective, alumina starts to soften way earlier at just 2072°C, while zirconia actually begins breaking down once temperatures hit over 2715°C. What really stands out about magnesium oxide is how well it holds up under constant exposure to temperatures above 2400°C without warping much. Because of this property, manufacturers rely on MgO for lining steelmaking ladles and building kilns used in glass production where maintaining structural integrity at such high temps is absolutely critical.

Thermal Conductivity and Resistance to Thermal Shock Under Cyclic Conditions

MgO has a thermal conductivity range of around 30 to 40 W/m·K, which isn't particularly high but what makes it stand out is how well it handles both heat transfer and resists thermal shock. Tests in real industrial settings have shown something pretty impressive: MgO crucibles retain about 95% of their original compressive strength even after going through 50 quick temperature swings from room temperature all the way up to 1800 degrees Celsius. Why does this happen? Well, the material's face centered cubic crystal structure plays a big role here. When temperatures change rapidly, cracks don't spread as easily through the material. Silica bricks tell a different story though. They tend to fail when exposed to these same extreme conditions because they undergo those annoying phase changes at specific points like 573 and 870 degrees Celsius, which basically causes structural breakdown.

Role of Purity in Maximizing Thermal Resistance and Minimizing Degradation

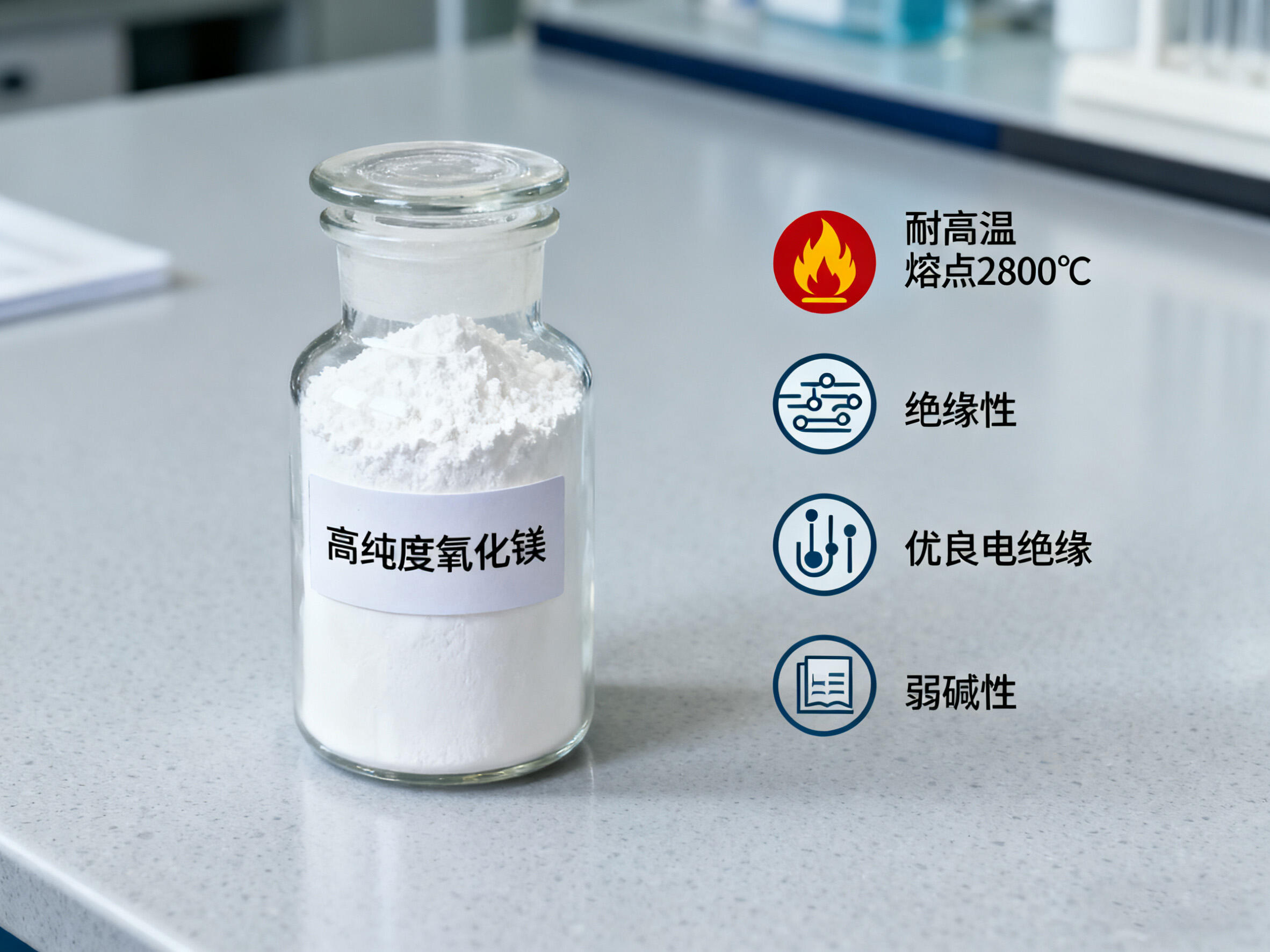

Magnesium oxide with high purity levels above 99% shows roughly 40% improved thermal stability compared to standard technical grade materials which typically range between 94% and 97% purity. When impurities such as calcium oxide get mixed in, they create these low melting phases that really speed up the corrosion at grain boundaries. Take silicon dioxide for example – even a small amount around 1% can actually drop the working temperature of MgO by about 150 degrees Celsius when used in basic oxygen furnaces. The fused magnesia production method gets us those ultra pure grades reaching nearly 99.9% purity. This makes a big difference in real world applications too, with refractories lasting anywhere from two to three times longer in tough environments like cement rotary kilns where conditions are extremely harsh.

Comparison with Other Refractory Materials: MgO's Advantages and Trade-Offs

| Property | MgO | Al₂O₃ | ZrO₂ |

|---|---|---|---|

| Max Operating Temp (°C) | 2,400 | 1,900 | 2,200 |

| Acid Resistance | Moderate | High | Low |

| Base Resistance | Excellent | Moderate | Excellent |

| Thermal Shock Resistance | High | Low | Moderate |

MgO excels in alkaline environments but requires protective coatings when exposed to acids. While zirconia provides superior insulation, MgO's 50% lower cost per ton and exceptional slag resistance make it the preferred choice for 78% of global steel producers.

Physical Structure and Mechanical Behavior of Magnesium Oxide

Crystal Structure, Density, and Influence on Material Durability

MgO has this face-centered cubic lattice arrangement that packs atoms really tightly together, resulting in a density above 3.58 grams per cubic centimeter. That's actually about 14 percent denser compared to those alumina ceramics we often see. Because of how closely packed everything is, magnesium oxide can handle compression forces well beyond 150 megapascals, which makes it pretty tough stuff when put under real stress conditions. What's interesting though is the way the ions bond so strongly inside the crystal structure. These bonds basically stop those tiny defects from moving around too much, and that explains why MgO holds up so well against creep even when things get hot. This property becomes especially important for materials used in high temperature environments where structural integrity matters most.

Hardness and Compaction Characteristics in Industrial Processing

With a Vickers hardness of 8.5 GPa comparable to hardened steel MgO also demonstrates 22% higher compactability than fused silica. These properties allow manufacturers to produce dense compacts (92 95% theoretical density) using standard 300 MPa hydraulic presses. This balance reduces wear on tooling while ensuring final products withstand rigorous thermal cycling.

Particle Size Distribution and Performance in Advanced Ceramic Applications

Chemical Inertness and Reactivity Profile of Magnesium Oxide

Controlled Reactivity With Water: Hydration to Magnesium Hydroxide

When magnesium oxide comes into contact with water, it typically produces magnesium hydroxide Mg(OH)₂. How fast this happens depends a lot on two factors: how much surface area is exposed and the crystal structure of the MgO. The really small particles of MgO in the 10 to 40 nanometer range react super quickly because they're so reactive at that scale. But when the material is sintered together into denser forms, it takes much longer to take in water. Studies looking at different heating processes show that baking MgO between around 800 degrees Celsius and 1,000 degrees gives the best results for building materials. At these temperatures, the material stays stable enough for construction purposes while still allowing for some controlled expansion when needed.

Resistance to Alkaline Environments and Effectiveness in Acid Neutralization

Magnesium oxide has a basic nature around pH 10.3 which means it doesn't react much in harsh alkaline conditions. That's why it holds up well in copper smelting slags while other materials made from alumina tend to break down over time. What makes MgO really useful though is how it tackles both sulfuric and hydrochloric acids pretty efficiently, somewhere between 0.9 to 1.2 grams per mole actually. When these reactions happen, they create stable salts like sulfates or chlorides that stay put instead of causing problems. Because of this two-fold ability, industries have found magnesium oxide indispensable for treating contaminated water and cleaning up emissions from industrial processes where sulfur removal is critical.

Oxidation Stability and Protective Barrier Function in Metallurgical Processes

Above 1,500°C, MgO forms a dense, non-porous layer on molten metal surfaces, reducing oxygen diffusion by 58% more effectively than silica-based refractories. This barrier decreases slag penetration in steelmaking furnaces by up to 72% and exhibits minimal reactivity with carbon, avoiding CO generation a key advantage for lowering process emissions.

Purity Grades and Industrial Performance Optimization of Magnesium Oxide

From technical grade to ultra-high purity: defining MgO performance tiers

The industrial magnesium oxide market has basically three main quality levels. The technical grade stuff, which contains around 85 to 92 percent MgO, works well for applications where budget matters most such as treating wastewater or building materials since it still provides decent resistance against chemicals. When we move up to higher purity versions between 95 and 99 percent MgO, these find their place in things like advanced ceramics manufacturing and making electrical insulators. Even slight improvements in purity here can cut down on those pesky dielectric losses by about 18 percent. At the top end sits ultra high purity MgO over 99.9 percent pure, typically made through vapor deposition techniques. This super clean material allows manufacturers to create transparent ceramics needed for powerful laser systems and forms the base for certain semiconductor components too.

Impact of common impurities (CaO, SiO₂, Fe₂O₃) on functional reliability

When calcium oxide (CaO) content goes over 1.2%, it speeds up how much refractory bricks deform under stress at around 1,600 degrees Celsius. The situation gets worse when silica (SiO2) is present at more than 0.8%. This causes harmful changes in the material's structure during repeated heating and cooling cycles. Even small amounts matter too. Iron oxide (Fe2O3) at just 0.3% can cut down on light passing through laser quality magnesium oxide by nearly a third. Researchers looking into this back in 2021 discovered something interesting though. They found that better processing methods for removing impurities actually cut failure rates from these contaminants by almost 9 out of 10 cases in high precision casting work.

FAQ

What is the primary use of magnesium oxide in industrial applications?

Magnesium oxide is primarily used in high-temperature applications such as lining steelmaking ladles, building kilns for glass production, and protecting spacecraft components due to its exceptional thermal stability.

How does the purity of magnesium oxide affect its performance?

Higher purity levels of magnesium oxide improve thermal stability and reduce degradation, making it suitable for more demanding applications such as advanced ceramics and cement rotary kilns.

What are the benefits of magnesium oxide's crystal structure?

Magnesium oxide's face-centered cubic crystal structure contributes to its high compressive strength and resistance to thermal shock, making it durable under extreme temperature variations.

Table of Contents

-

Thermal Stability and High-Temperature Performance of Magnesium Oxide

- Exceptional Melting Point Enabling Use in Extreme-Temperature Environments

- Thermal Conductivity and Resistance to Thermal Shock Under Cyclic Conditions

- Role of Purity in Maximizing Thermal Resistance and Minimizing Degradation

- Comparison with Other Refractory Materials: MgO's Advantages and Trade-Offs

- Physical Structure and Mechanical Behavior of Magnesium Oxide

- Chemical Inertness and Reactivity Profile of Magnesium Oxide

- Purity Grades and Industrial Performance Optimization of Magnesium Oxide

- FAQ